Traceability Solutions

RFID & QR for Connected Identity.

Built for the Real World.

Watermill works in partnership with its customers to design and deliver practical, scalable traceability solutions – supplying traceability labels directly, and providing independent advisory on the systems, hardware, and wider ecosystem required to keep those solutions dependable over time.

An Introduction to Traceability Solutions

In practice, only two technologies enable traceability at scale: QR codes and RFID. They address different parts of the same problem and should not be seen as alternatives. Instead, they are complementary building blocks for effective identification and traceability. Most successful traceability solutions use both, applying each where it provides the greatest operational and economic value. QR codes offer simplicity and accessibility, while RFID enables automation and high-volume data capture.

Watermill helps customers determine where simplicity is sufficient and where automation materially improves performance.

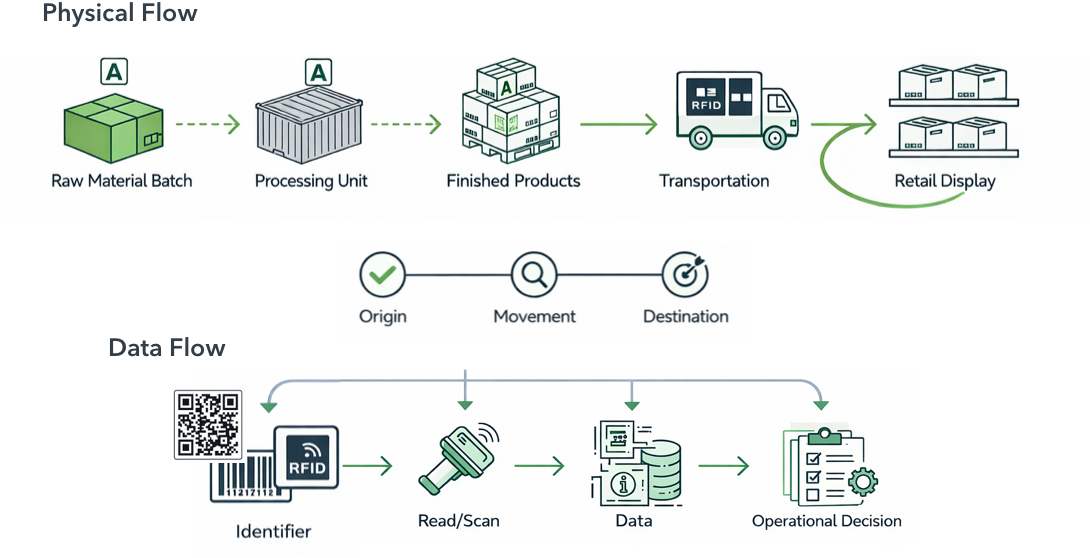

Traceability is about maintaining reliable visibility and control as products move through operations, change hands, and interact with systems. At scale, this depends on how consistently a product can be identified, recognised, and referenced across locations, partners, and processes.

Barcodes

Low cost, widely adopted, and effective where line-of-sight and manual interaction are sufficient

RFID

Enabling automatic identification, bulk reading, and interaction without direct visibility, even in complex environments

Traceability Journey: Identity Continuity

Traceability is not a single technology or platform. It is an identification framework that connects physical products to digital systems as they move, are handled, and undergo changes of state. That framework typically includes:

A physical identifier on the product (barcode, RFID, or a hybrid)

Read or scan events at defined operational points

Systems that consume and act on the data

Processes that rely on the data being accurate and timely

Watermill helps customers design this framework so that it continues to work in real operations, not just controlled pilot environments.

Common Challenges in Traceability Programmes

Across industries, traceability initiatives often need to balance:

Cost versus performance

Manual processes versus automation

Pilot success versus operational scale

Environmental and handling constraints

Multiple systems and stakeholders

How Watermill Works with Its Customers

Watermill combines direct label supply with independent advisory. We work with our customers to:

Design and supply traceability labels (barcode, RFID, hybrid)

Define identification and serialisation structures

Encode and verify identity before release

Advise on traceability systems and required hardware

Act as a mediator across wider partner ecosystems where needed

This partnership approach enables customers to build traceability solutions that remain compliant, efficient, and dependable as their operations evolve.